Introduction

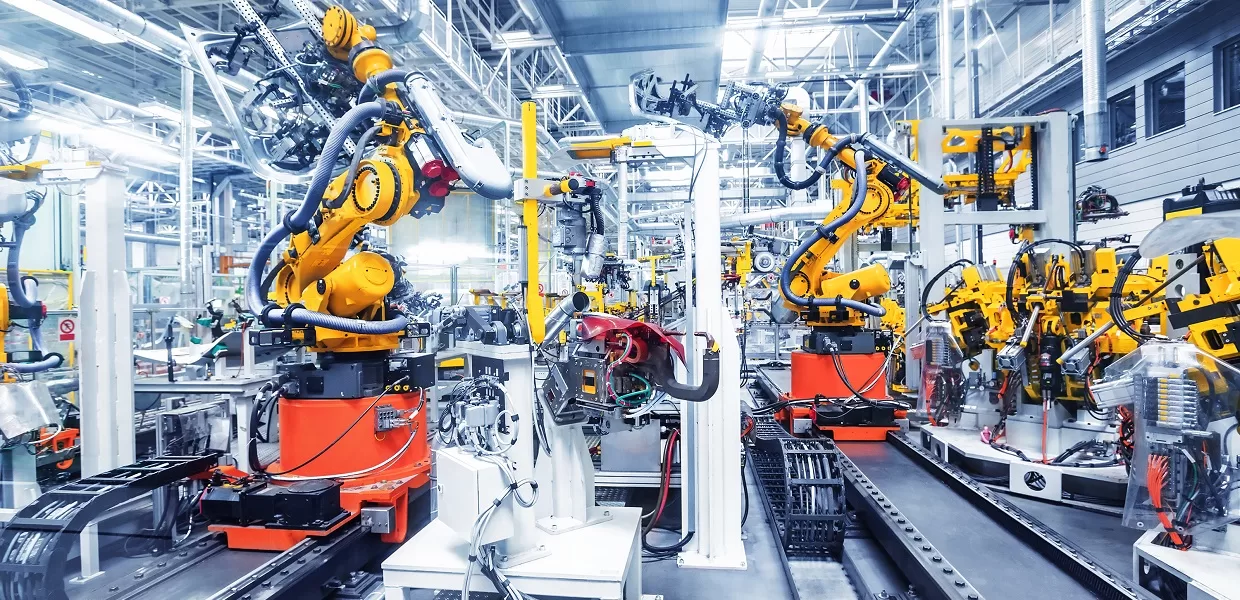

The Industrial Internet of Things (IIoT) represents a critical evolution in the industrial sector, merging operational technology with advanced information technology to create systems that are not only interconnected but also intelligent. The integration of 5G technologies promises to propel this evolution forward by offering higher data rates, reduced latency, and enhanced reliability—attributes that are essential for the rigorous demands of industrial applications.

Concurrently, in 3GPP Release-16, Time-Sensitive Networking (TSN) has emerged as a foundational technology for achieving deterministic communication within industrial networks, crucial for operations requiring precise timing and synchronization.

This integration is designed to streamline the adoption of wireless technologies in traditionally wired environments, such as manufacturing floors and automated production lines, thereby enhancing flexibility without compromising the operational precision required by such applications.

Architectural Framework for 5G-Enabled IIoT

The integration of 5G and Time-Sensitive Networking (TSN) into IIoT necessitates a robust architectural framework that can accommodate the high demands of industrial environments. This framework must not only ensure seamless interoperability between 5G and existing wired TSN systems but also provide the flexibility and scalability required for future expansions and technology shifts.

Centralized Network Management and Network Synchronization

A key component of the 5G-TSN architectural framework is centralized network management. This model is predicated on the notion that all network elements, from gateways and routers to individual sensors and actuaries, are orchestrated by a central network controller (CNC).

This controller is responsible for the configuration and management of the network, ensuring that all devices operate synchronously and adhere to the stringent timing and reliability requirements of industrial applications.

Under the centralized management model, synchronization is achieved through the IEEE802.1AS protocol, allowing for sub-microsecond synchronization across all devices. This is crucial in environments where operations are highly sensitive to delays, such as in automated assembly lines.

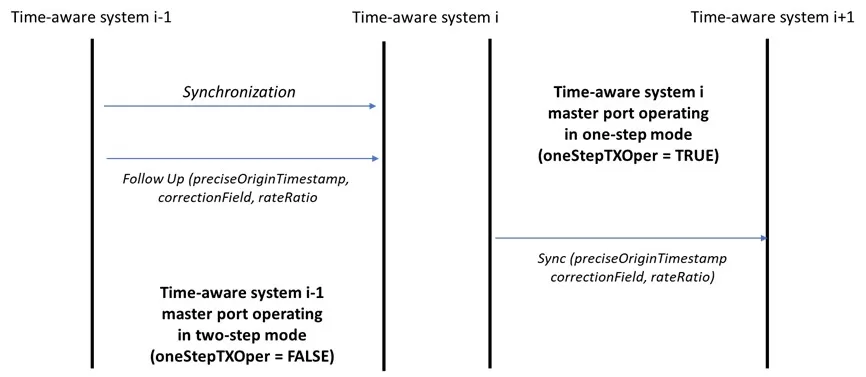

Figure 1: Transmission of time synchronization information in IEEE Standard 802.1AS

Synchronizing the timing of devices is essential for the reliable performance of time-sensitive applications. The standard method for this is the IEEE 802.1AS Precision Time Protocol (gPTP), which aligns clocks across an Ethernet network. This synchronization supports scheduled traffic and filtering within Time-Sensitive Networking (TSN), enabling devices to operate in unison based on a common time reference.

In practice (Figure 1), a primary clock, the grandmaster, shares the time with connected devices. These devices adjust the time they receive to account for any delays, ensuring all clocks across the network remain in sync. For example, a device will correct the received time based on how long the signal took to arrive and then relay that time to the next device in the network, maintaining a chain of precise timing.

Integration of Wireless and Wired Systems

To incorporate 5G into existing TSN infrastructures effectively, the architectural framework adopts a dual approach:

- Mimicking Ethernet Bridges: The 5G system mimics the behavior of Ethernet bridges within the industrial setup. Each 5G endpoint (User Equipment – UE) acts as a port on the virtual bridge, thus facilitating the integration with minimal disruption to the existing network architecture.

- Translator Functions: To ensure seamless data flow between the IEEE TSN and 3GPP standards, translator functions are employed at strategic points within the network. These translators handle discrepancies in flow control and quality of service parameters, ensuring that both wired and wireless segments of the network can communicate effectively without data loss or delay.

Flexible and Scalable Infrastructure

The architectural framework is designed to be inherently flexible, allowing for easy scaling and adaptation to accommodate new industrial applications and expansions. This flexibility is achieved through:

- Modular Design: Components within the network, such as translators and controllers, are modular, allowing for easy upgrades and replacements as technology evolves.

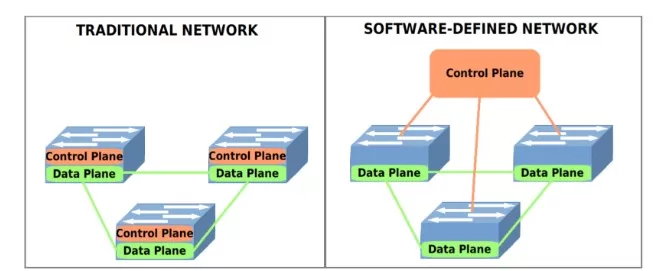

- Software-Defined Networking (SDN): The use of SDN principles enables dynamic resource management and virtualization of network functions, which further enhances the network’s ability to adapt to changing demands.

Figure 2: Comparison between Traditional Network and SDN

This architectural framework sets the foundation for deploying 5G in industrial environments, where reliability and precision are paramount. By addressing the integration challenges head-on and leveraging the strengths of both 5G and TSN, the framework ensures that industrial enterprises can not only maintain but enhance their operational efficiencies in the era of IIoT.

Technical Enablers and Innovations

The successful integration of 5G and Time-Sensitive Networking (TSN) into the Industrial Internet of Things (IIoT) is underpinned by a series of technical enablers and innovations. These advancements are pivotal in ensuring that the new network infrastructure can meet the exacting demands of industrial automation with unmatched precision and reliability.

Time-Sensitive Communications (TSC)

One of the cornerstone innovations in 3GPP Release-16 is the introduction of Time-Sensitive Communications (TSC). TSC provides the necessary tools for deterministic transport and accurate synchronization across the network, which are essential for seamless operation in time-critical industrial applications.

- Deterministic Transport: TSC enables the network to handle data traffic in a predictable and reliable manner, ensuring that time-sensitive data packets reach their destinations within stringent deadlines. This is crucial for applications where even microsecond delays can lead to significant disruptions.

- Absolute Time Synchronization: Alongside deterministic transport, TSC facilitates precise synchronization of all networked devices. This capability ensures that all components within the industrial ecosystem operate in complete harmony, which is vital for processes that require coordinated timing across multiple devices.

Translator Functions Between IEEE TSN and 3GPP

A significant challenge in merging 5G with TSN is the disparity in their respective protocols and standards. Translator functions are employed to bridge this gap, facilitating seamless communication between the two systems:

- Flow Control and QoS Adaptation: These functions convert TSN-specific commands and configurations into equivalent 5G parameters and vice versa. This ensures that the network adheres to the strict quality of service and flow control requirements inherent to industrial applications.

- Location of Translators: Strategically placed at both the device (UE) and network (CN port) sides, these translators play a crucial role in maintaining the integrity and timeliness of the data transmitted across the network.

Enhancements in Network Management and Traffic Handling

Release-16 also introduces improvements in how the network handles traffic and manages resources, critical for supporting the complex needs of IIoT environments:

- Semi-Persistent Scheduling (SPS): This feature allows for periodic traffic to be scheduled in advance, reducing latency by bypassing the need for dynamic scheduling for each data transfer.

- Proactive Resource Allocation: By anticipating the needs of periodic traffic, the network can allocate resources more efficiently, ensuring that critical data flows are not interrupted.

These technical enablers and innovations form the backbone of the 5G-TSN integration, providing the necessary tools to achieve a high-performance, reliable, and synchronized network infrastructure suited to the demands of modern industrial environments. By leveraging these advancements, industries are well-positioned to harness the full potential of IIoT, driving efficiency and innovation in their operations.

Economic and Operational Impacts

The integration of 5G technologies with Time-Sensitive Networking (TSN) in the Industrial Internet of Things (IIoT) environment promises significant economic and operational benefits, but it also presents substantial challenges. Understanding these impacts is crucial for industries considering investing in this advanced infrastructure.

Economic Benefits

Cost Efficiency and ROI:

The implementation of 5G in industrial settings can lead to considerable cost savings over time. By reducing latency and increasing data throughput, 5G enables more efficient operation of automated processes, which can decrease downtime and reduce maintenance costs. Additionally, the enhanced capabilities of 5G to handle more data can improve decision-making processes, potentially leading to better resource management and lower operational costs.

Investment in Infrastructure:

While the initial outlay for 5G infrastructure, including new equipment and system upgrades, can be high, the long-term return on investment (ROI) can be significant.

Enhanced efficiency reduced operational costs, and the potential for new services and products provide a compelling case for this investment. However, companies must carefully plan and phase their investments to match their operational needs and financial capacity.

Operational Impacts

Enhanced Flexibility and Scalability: With 5G and TSN, industries gain unprecedented flexibility in managing and scaling their operations. The ability to reliably connect a greater number of devices in real-time allows for more comprehensive monitoring and control systems, which can adapt more dynamically to changing operational conditions. This scalability is particularly beneficial for sectors such as manufacturing and logistics, where operational needs can vary significantly.

Improved Reliability and Reduced Latency: The low latency and high reliability of 5G are pivotal in environments where millisecond delays can result in significant operational disruptions. For example, in automated production lines, the timely and synchronized operation of machinery and robotics is essential. 5G’s ability to provide fast, reliable communications helps ensure that these systems can operate without delays, enhancing overall productivity and safety.

Increased Data-Driven Decision Making: The high data throughput of 5G enables more comprehensive data collection and analysis. This capability allows companies to leverage big data analytics more effectively, leading to improved operational insights and more informed decision-making. With more accurate and timely data, businesses can optimize processes, reduce waste, and respond more quickly to market or environmental changes.

Future Directions and Technological Advancements

The integration of 5G and TSN into IIoT is set to transform industrial operations, but this is just the beginning. As technology evolves, future advancements are anticipated to further enhance connectivity, efficiency, and automation capabilities. This section explores potential future directions and technological advancements that could influence 5G-TSN integration in IIoT environments.

Edge Computing: The convergence of 5G and edge computing is expected to dramatically improve data processing speeds and reduce latency. By processing data closer to where it is generated, edge devices can perform real-time data analysis without the need to transmit large volumes of data back to a central server. This integration not only speeds up response times but also reduces bandwidth usage, which is critical for bandwidth-intensive industries like manufacturing and logistics.

Open Radio Access Network (O-RAN): Future advancements in O-RAN technology are set to revolutionize 5G architectures by promoting more flexible and scalable networks. O-RAN allows for greater customization of network functions through software-based configurations, which can dynamically adapt to the needs of IIoT applications, thereby enhancing efficiency and reducing costs associated with hardware.

Predictive Maintenance: Integrating AI and machine learning models with 5G-enabled IIoT devices can significantly improve predictive maintenance capabilities. By analyzing data collected from sensors in real-time, AI algorithms can predict equipment failures before they occur, thereby minimizing downtime and maintenance costs.

Conclusion

In conclusion, the advanced integration and robust architectural framework of these technologies have been meticulously designed to meet the high-performance demands of industrial environments, paving the way for smarter, more connected, and highly efficient systems.

The future of 5G and TSN integration in IIoT holds promises, driven by advancements in edge computing, artificial intelligence, network slicing, and more. These innovations will not only enhance the capabilities of industrial networks but also open new possibilities for automation, efficiency, and sustainability in industrial settings.

As these technologies mature, they will create a robust ecosystem that will fundamentally transform how industries operate and compete in the digital age.

References

- IEEE 802.1AS-2011 “IEEE standard for local and metropolitan area networks – Timing and synchronization for time-sensitive applications”

- 3GPP TS 23.501, System Architecture for 5G System

- 3GPP TS 23.502, Procedures for 5G System

- https://www.precedenceresearch.com/industrial-iot-market