Introduction

The emergence of Digital Twin technology in the Industrial Internet of Things (IIoT) offers a groundbreaking integration of the real and virtual worlds, presenting a real-time digital mirror of physical objects, processes, and systems. Going beyond a mere digital replica, Digital Twins tap into a vast network of sensors to capture a continuous data stream, which, when combined with edge and cloud computing, becomes the essence of the Digital Twin.

Industries such as manufacturing, automotive, energy, agriculture, and healthcare are poised to benefit enormously, with the digital twin market expected to witness significant growth.

However, like any innovative technology, it’s not without challenges. In this article, we’ll dive into what Digital Twin is, how it connects with IIoT, and why it’s a game-changer for many industries.

What is a Digital Twin?

The concept of a Digital Twin is not just about creating a one-to-one digital model of a physical asset. It’s about the live data streams that flow from countless embedded sensors, the intelligence layered atop that data, and the real-time insights and actions drawn from it. As industries accelerate their shift towards digitization, automation, and advanced analytics, the Digital Twin stands out as an emblematic manifestation of this shift. It reflects a world where the lines between the physical and digital blur, paving the way for unprecedented levels of efficiency, innovation, and adaptability.

As companies aim to keep up with modern industry changes, digital twin technology is becoming more and more important.

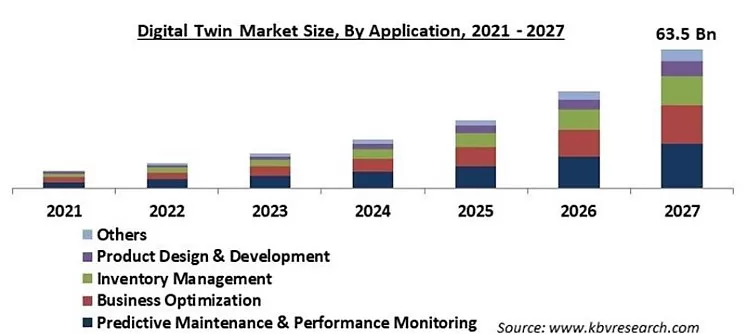

Figure 1: Growth trends in the digital twins market

How much companies earn from digital twins will depend on how they decide to make money from it.

Based on data sourced from KBV Research, the entire market spectrum for Digital Twin applications is set to escalate, reaching an impressive 63.5 billion by 2027. The biggest growth areas are in Predictive Maintenance & Performance Monitoring and Business Optimization. This means companies are using Digital Twins mainly to check their machines’ health and improve their business. At the same time, other uses like Product Design & Development and Inventory Management remain popular.

For industries that deal with complex and costly projects, the focus will be on using digital twins to save money and work more efficiently. This means they will need good software and tools to get the most out of digital twins.

Architectural Framework of Digital Twin Technology

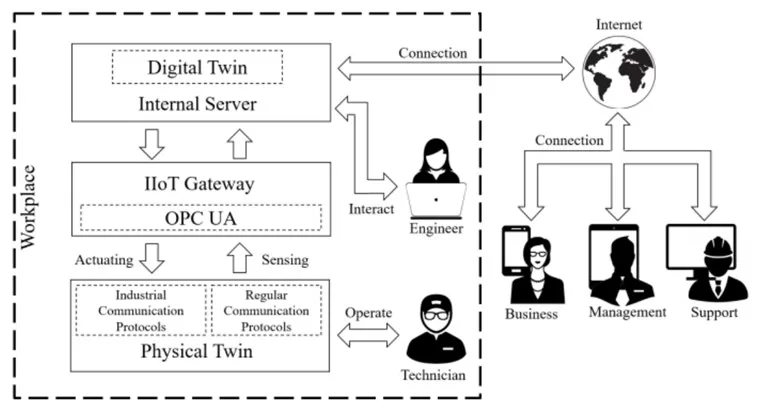

The Digital Twin, in its essence, isn’t just a single entity; it’s a composite of interconnected components and layered structures, which together provide a comprehensive digital representation of its physical counterpart. Figure 2 portrays the intricate architecture of the Digital Twin in the realm of Industrial Internet of Things (IIoT). This architectural framework can be broadly segmented into three main structures:

Figure 2: Digital Twin Architectural Framework

- Physical Twin (PT): This represents the actual manufacturing processes. It communicates using both regular and industrial communication protocols. Typically, in industrial scenarios, these PTs encompass manufacturing and assembling processes. They are outfitted with multiple sensors and actuators that function under various industrial protocols throughout the facility.

- IIoT Gateway: Acting as the bridge, the IIoT Gateway facilitates communication between the PT and the Internal Server. This is achieved through IIoT devices and a wired connection. The gateway, positioned in this layer, is crucial for collecting data from the environment – a hallmark feature of both IoT and IIoT. It utilizes various sensors placed around the PT, working in conjunction with single-board computers operating under IIoT technologies. Not only does this gateway gather information from these sensors, but it also uploads it to the Internal Server and translates the Digital Twin commands for actuation on the PT. Data bundling is executed under the OPC UA Extensible Markup Language (XML) standard, offering a unified communication structure across diverse layers. The advantage of the XML file format is its simplistic structure, which facilitates seamless data processing across various devices.

- Internal Server: This is the computational heart of the system, housing the Digital Twin and running simulations. The server manages the user system, offers visual representation, and undertakes process analysis. It determines user access to the Digital Twin’s functions based on authorization and contextual circumstances. All the gathered data is then visualized using shapes, colors, figures, and motions, thereby aiding in contextual interpretation. In terms of process analysis, it evaluates data pertinent to the state of the physical processes, identifying any faults or unusual behavior. Within this layer, the Digital Twin showcases the PT’s objects and processes in terms of their shapes, status, movements, and values. This visualization ensures that control and supervision are more intuitive and responsive for the human operator. While there are multiple ways to display this virtualization (e.g., 3D model, 2D model, virtual reality), the chosen method should align with system requirements like real-time response, cybersecurity, intuitive representation, and reliability. Another salient feature of the Digital Twin is its ability to display process information and grant access based on the user’s position within the company and their access location.

Outside the workplace, the Digital Twin provides insights into processes, supply, and demand, adjusting the displayed information according to the user’s interests. Internally, it deals with critical operations, offering a detailed perspective on processes.

The proposed architecture emphasizes the seamless integration of physical processes with their digital counterparts, harnessing the power of IIoT. This not only enhances operational efficiency but also ensures that data-driven insights are available for better decision-making.

Integration of Digital Twins with IIoT Systems

The integration of Digital Twins with Industrial Internet of Things (IIoT) systems unveils an innovative landscape for advanced manufacturing and industrial operations. With IIoT’s interconnected devices and real-time data streams, Digital Twins find a fertile ground to simulate, predict, and optimize in unprecedented ways. Let’s delve into how these two powerful paradigms come together.

Enhanced Data Acquisition Capabilities

- Broadened Sensor Array: IIoT systems are renowned for their extensive array of sensors. When integrated with Digital Twins, these sensors provide more granular data, capturing every conceivable parameter from the physical system.

- Remote Monitoring: With IIoT’s capability to transmit data over vast distances, Digital Twins can simulate and optimize systems situated in remote or inaccessible locations.

Real-time System Interactions

- Immediate Feedback: IIoT systems can instantly relay changes or anomalies in the physical system to the Digital Twin. This enables real-time updates and adjustments, whether it’s averting a potential fault or optimizing a process.

- Dynamic Simulations: With continuous data streams, Digital Twins can run dynamic simulations reflecting the current state of the physical system, allowing stakeholders to visualize and understand ongoing processes in detail.

Feedback Loop from Digital to Physical

- Actionable Recommendations: The insights and decisions birthed within the Digital Twin are of little value unless enacted in the real world. Hence, actionable recommendations are communicated back to the physical system’s controllers or operators.

- Automated Controls: In more advanced setups, the Digital Twin can directly interface with the physical system’s controllers. This allows for automated adjustments based on the insights, ensuring optimal performance without human intervention.

- Model Refinement: As the physical system evolves or as new data comes to light, the Digital Twin’s underlying models might need refinement. This iterative feedback helps in continually refining the digital representation to better mirror and predict the physical system’s nuances.

Advanced Analytical Insights

- Predictive Analytics: Leveraging the historical and real-time data from IIoT devices, Digital Twins can forecast future system states, predicting wear and tear, potential failures, or maintenance needs.

- Optimization Algorithms: Combining IIoT’s extensive data with the computational capabilities of Digital Twins allows for the deployment of advanced optimization algorithms. These algorithms can suggest operational tweaks, resource allocation strategies, or energy-saving measures.

Automated and Adaptive Responses

- Direct Control Capabilities: Some advanced IIoT setups allow Digital Twins to not just suggest but also implement changes directly. For instance, if a Digital Twin predicts an overheating scenario in machinery, it can command the IIoT system to reduce the machine’s operational intensity or increase cooling.

- Adaptive Learning: As the IIoT system evolves, the Digital Twin can adapt its models and simulations accordingly. This continuous learning ensures the twin remains an accurate reflection of its physical counterpart.

This integration offers industries the promise of reduced operational costs, heightened efficiencies, minimized downtimes, and a deeper understanding of their systems, laying the foundation for the next wave of industrial revolution.

Challenges in Implementation

As the utilization of Digital Twins in the IIoT realm grows, so too does the recognition of the hurdles that need to be addressed. Acknowledging these challenges, along with the opportunities they present, is vital for shaping the future of Digital Twin technology and its integral role in the IIoT ecosystem.

- Data Security and Privacy

As Digital Twins accumulate vast amounts of data, concerns about data breaches and unauthorized access arise.

Implementing advanced encryption methods, robust authentication processes, and considering blockchain for data integrity are steps towards ensuring data security.

- Integration with Legacy Systems

Many industries operate with legacy systems that may not be immediately compatible with the latest Digital Twin technologies.

Crafting middleware solutions and transitional technologies can help bridge the gap between old and new, allowing for a more seamless integration.

- High Initial Costs

Setting up a comprehensive Digital Twin system requires significant initial investment, which might deter small to medium enterprises.

The development of scalable Digital Twin solutions that allow businesses to start small and expand as they see returns can make the technology more accessible.

- Real-time Data Processing

The necessity for real-time data processing can strain existing infrastructure, leading to latency issues.

Incorporating edge computing can localize data processing, reducing latency and ensuring real-time responsiveness.

The Road Ahead

While the challenges are real and substantial, they represent a roadmap for continuous refinement and innovation. The future of Digital Twins in IIoT is bright, marked by advancements that will further bridge the physical and digital realms. As technologies like quantum computing and AI continue to evolve, and as industries recognize the inherent value of real-world, real-time simulations, the Digital Twin paradigm will undoubtedly shift from being a luxury to a necessity.

Collaborative efforts between industries, academia, and governments can accelerate the adoption and optimization of Digital Twin technology. Ultimately, this convergence of effort, innovation, and necessity promises a smarter, more efficient, and interconnected future for the world of IIoT.

Conclusion

Digital Twin technology is changing how we use the IIoT. Even though it has great potential, there are still challenges to face. But with help from experts, businesses, and governments, we can use this tool to make industries smarter and more connected. The future looks bright as we blend the real and digital worlds together.

References

- Vinicius Souza, “A Digital Twin Architecture Based on the Industrial Internet of Things Technologies”, IEEE

- Fuller et al.: Digital Twin: Enabling Technologies, Challenges and Open Research, IEEE, 2020

- Hanan Amthiou, “Digital Twins in Industry 4.0: A Literature Review”, https://doi.org/10.1051/itmconf/20235201002