Introduction

The Industrial Internet of Things (IIoT) stands at the forefront of the fourth industrial revolution, transforming manufacturing and industrial processes through smart, connected devices. At the heart of this transformation are industrial sensors, which collect critical data for monitoring, control, and optimization. The introduction of 5G NR Light, specifically the enhancements in 3GPP Release 18 NR-RedCap (Reduced Capability), marks a significant milestone in the evolution of IIoT, offering new opportunities and solutions for industrial sensor applications. This article delves into the technical requirements of industrial sensors and explores how NR-RedCap Release 18 serves as a game-changer in the IIoT landscape.

Technical Requirements for Industrial Sensors

Industrial sensors serve as the backbone for monitoring and controlling various industrial processes by accurately capturing data on temperature, pressure, vibration, flow, and more.

Table 1: Technical Requirements for Industrial Sensors

| Characteristic | Requirement |

| Data Rate | < 2 Mbps |

| Latency | < 100 ms |

| Availability/Reliability | 99.99% |

| Battery Lifetime | Several years (optimized for low power consumption) |

| Environmental Robustness | High (able to withstand harsh industrial conditions) |

| Scalability | High (supports large numbers of sensor deployments) |

| Security | High (secure communication channels to protect data) |

These sensors are engineered to meet specific challenges and operational demands in industrial settings:

- Data Rate: They are designed to handle data rates of less than 2 Mbps, ensuring efficient data capture and transfer without overburdening the network.

- Latency: With a requirement for latency under 100 ms, industrial sensors support real-time data transmission that is essential for maintaining operational efficiency and ensuring safety in dynamic industrial environments.

- Availability and Reliability: The sensors exhibit an exceptional availability and reliability rate of 99.99%, signifying their capability to function consistently and dependably, even in the most challenging conditions.

- Battery Lifetime: To cater to the needs of industrial applications where power sources may be scarce or non-existent, these sensors are optimized for low power consumption, enabling them to operate for several years without the need for battery replacement.

- Environmental Robustness: Industrial sensors are built to be robust, capable of withstanding harsh environments that are often characterized by extreme temperatures, vibrations, and potential exposure to corrosive substances.

- Scalability: In consideration of industrial environments that may require a vast network of sensors, the designs of these devices accommodate scalable connectivity to facilitate the deployment of potentially thousands of units.

- Security: Recognizing the sensitive and critical nature of the data they collect, industrial sensors employ secure communication channels to safeguard against cyber threats and prevent unauthorized access.

These specifications underscore the crucial role that industrial sensors play in the automation and monitoring of industrial processes.

Their design reflects a careful balance between performance and endurance, ensuring that they not only meet the immediate demands of data collection but also integrate seamlessly into the broader objectives of industrial efficiency, safety, and scalability.

Battery Enhancement

Power saving techniques that enable a longer battery lifetime were first introduced in Release 17. In 3GPP Release 18 several enhancements that directly address the requirements of industrial sensors, making it a game-changer in the IIoT space:

Extended Discontinuous Reception (eDRX) Mechanism

The intermittent nature of data communication in IIoT applications—characterized by sporadic bursts of data transmission followed by extended periods of silence—necessitates a power management strategy that minimizes energy consumption during downtime.

In 5G, DRX cycles configured by the network range from a few hundred milliseconds to 2.56 seconds, tailored to downlink latency needs. The Discontinuous Reception (DRX) mechanism allows devices to enter a “deep sleep” mode during periods of inactivity. The sleep mode significantly reduces power consumption by shutting down non-essential functions and only “waking” the device for scheduled check-ins with the network.

Release 17 expanded this with eDRX for RedCap devices, extending cycles up to 3 hours in RRC Idle mode and 10.24 seconds in RRC Inactive mode, mirroring the capabilities of NB-IoT and offering comparable power savings.

Release 18 plans to extend the maximum eDRX cycle in RRC Inactive mode to approximately three hours, aligning it with the benefits seen in RRC Idle mode.

The flexibility in configuring eDRX cycles, tailored to the specific data transmission needs of various IIoT applications, ensures that devices can conserve energy without compromising their operational readiness or data transmission latency.

Radio Resource Management (RRM) for Stationary Devices

Industrial environments often deploy sensors and devices that remain static, monitoring conditions without the need for mobility.

Release 16 first introduces Radio Resource Management (RRM) protocols for stationary devices. By reducing the frequency of network quality assessments—measurements that typically consume significant power—NR-RedCap devices can conserve energy without sacrificing connectivity quality. This optimization is particularly beneficial in stable industrial environments where network conditions are unlikely to fluctuate dramatically, allowing devices to focus energy use on essential data transmission tasks.

Release 17 introduced enhanced measurement relaxations for RedCap, offering greater flexibility and supporting new scenarios beyond those in Release 16. This includes extended periods without neighbor cell measurements and specific relaxations for stationary scenarios, significantly enhancing RedCap device battery life.

Additionally, eDRX settings for RedCap devices in RRC Idle or Inactive states, combined with these relaxed measurements, further boost battery efficiency beyond what’s possible with RRM measurement relaxation alone.

Unlike regular 5G devices in RRC Connected state, which don’t support relaxed RRM monitoring, RedCap introduces mechanisms to identify low mobility scenarios and communicate this to the network. This allows for optimized measurement configurations, contributing to additional battery life improvements.

These advancements in measurement relaxation are anticipated to extend battery life significantly, meeting the demands of various RedCap use cases.

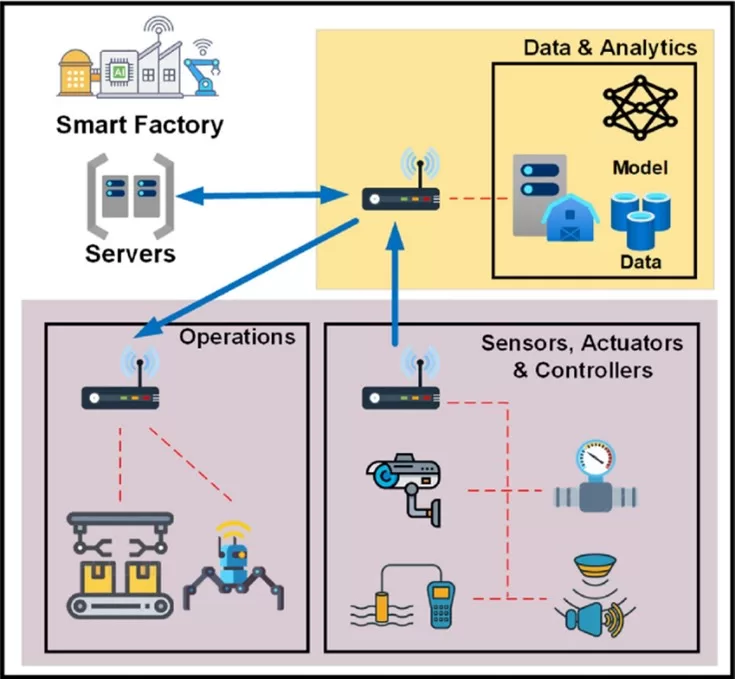

Use Case: Smart Factory Wireless Sensors

Within a smart factory environment, NR-RedCap devices function as pivotal links between the physical and digital worlds. Their design facilitates a seamless and robust integration into the existing industrial communication frameworks, enabling real-time data acquisition and control.

These sensors, along with actuators and controllers, are the sentinels and effectors in the cyber-physical systems, where they:

- Gather Precision Data: NR-RedCap equipped sensors are capable of measuring intricate details in factory operations, such as temperature variations, vibration frequencies, and pressure fluctuations, with enhanced accuracy and reduced latency.

- Enable Predictive Maintenance: By transmitting data to on-site servers and data analytics platforms, these devices enable predictive maintenance models that can foresee and prevent equipment failures, minimizing downtime and reducing operational costs.

- Support Scalable Deployment: With the reduced complexity and power requirements outlined, NR-RedCap devices can be deployed more densely within a factory setting, ensuring comprehensive monitoring and control.

- Facilitate Real-time Analysis: The streamlined data delivery to data and analytics platforms supports complex algorithms and machine learning models, enabling real-time optimization of factory operations based on immediate data inputs.

- Operate in Harsh Conditions: The robustness of RedCap devices ensures reliable operation even in the adverse conditions commonly found in industrial settings, thereby maintaining consistent data flow and operations control.

Future Work and Research

RedCap devices introduced in Release 17 are similar to some older LTE devices but are ready to switch over to the newer 5G networks. They are designed to replace LTE devices as we move more towards using 5G. Their design makes it easy to build devices that can work with both LTE and 5G if necessary.

In Release 18, a new type of RedCap device will come out. It will have a top speed of about 10 Mbps, which is not too high but suitable for simple IoT needs. Even though these new devices are simpler than the first RedCap devices, they won’t be much less complex.

These RedCap devices also offer better location tracking, which is important for IoT. This improved feature is part of the updates coming in Release 18.

5G can handle more types of frequencies and more devices than LTE, so RedCap devices could be used in new ways, especially where LTE is not available.

From the network infrastructure perspective, RedCap device support is envisioned as a software-based network enhancement, circumventing the need for additional hardware investments. It’s important to recognize that RedCap is designed to employ the same spectrum sharing techniques as standard NR, facilitating a harmonious coexistence of various device types (LTE, LTE-M, NB-IoT, NR, RedCap) within the same network cell, optimizing spectral efficiency and device interoperability.

Conclusion

NR-RedCap is set to revolutionize the Industrial Internet of Things (IIoT), especially for smart factory applications. With capabilities like enhanced precision data gathering, predictive maintenance, and robust operation in extreme conditions, RedCap devices enable more dense and efficient sensor deployment.

Furthermore, power saving innovations like extended eDRX cycles and optimized radio resource management contribute significantly to prolonged battery life, crucial for industrial sensors.

The transition from LTE to 5G will allow RedCap to support a wider range of IoT applications and frequencies, improving positioning accuracy for IoT use cases.

Importantly, network integration for RedCap devices is expected to be straightforward, requiring just software updates, and will maintain compatibility with existing spectrum sharing techniques. All these factors position NR-RedCap as a critical component in advancing IIoT towards greater efficiency and scalability.

References

- Xingqin Lin, “An Overview of 5G Advanced Evolution in 3GPP Release 18”, IEEE Communications Standards Magazine

- 3GPP TR 23.700-68, “Study on RedCap Phase 2”, 2023

- Matteo Pagin et al, “5G NR-Light at Millimeter Waves: Design Guidelines for Mid-Market IoT Use Cases”, IEEE Access 2021;

- Industrial Wireless Sensor Networks. http://dx.doi.org/10.1016/B978-1-78242-230-3.00011-8