Introduction to Edge Computing in IIoT

The landscape of the Industrial Internet of Things (IIoT) is witnessing a transformative shift, with edge computing emerging as a pivotal technology redefining data processing and real-time analytics in industrial environments.

Edge computing represents a paradigm where computation is largely or completely performed on distributed device nodes known as smart devices or edge devices, as opposed to primarily taking place in a centralized cloud environment. This approach not only alleviates the burden on cloud resources but also significantly reduces latency, making it an ideal fit for industries where real-time data processing is critical.

The transition to edge computing in IIoT is driven by the increasing need for real-time data analysis, reduced latency, and localized decision-making in various industrial processes. These include manufacturing, logistics, energy management, and other sectors where prompt data-driven decisions can lead to enhanced operational efficiency, predictive maintenance, and optimized resource allocation.

Technical Foundations of Edge Computing in IIoT

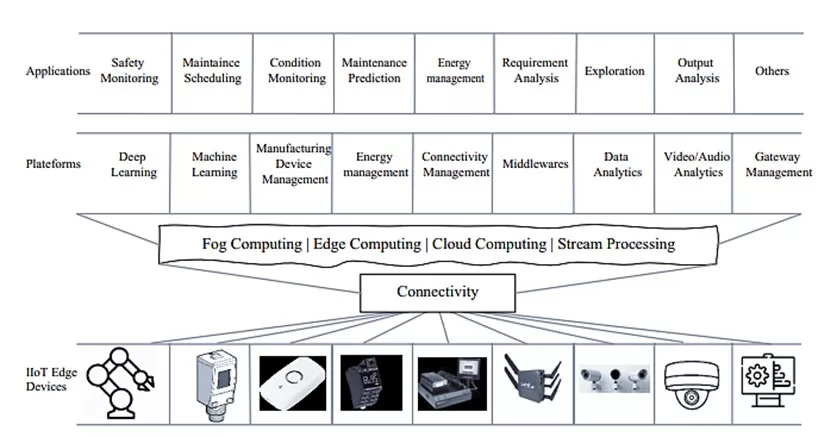

At the foundation, IIoT edge devices act as the sensory and actuation points, capturing real-time data and initiating actions within the industrial landscape. These devices communicate through an intricate network that encompasses fog, edge, cloud computing, and stream processing, ensuring a seamless flow of information.

Embedded within this network are robust processing platforms equipped with deep and machine learning capabilities, diligently analyzing data to refine operational efficiencies and predictive maintenance models. They serve pivotal roles in device management, energy conservation, and ensuring continuous connectivity, supported by middleware that facilitates the integration of diverse software and hardware components.

Figure 1: IIoT Edge Computing Architecture

The upper echelon of this architecture is dedicated to a suite of applications designed to enhance industrial safety, monitor conditions, predict maintenance needs, and manage energy with precision. This tier also delves into analyzing requirements and outputs, ensuring that the industrial processes align with set standards and expectations.

This edge computing architecture encapsulates the essence of IIoT, transforming it into a dynamic, intelligent network capable of self-optimization and real-time decision-making, paving the way for a future of autonomous industrial operations.

Enhancing Real-Time Data Analytics and Decision-Making

In the Industrial Internet of Things (IIoT), the capacity for real-time data analytics and decision-making is not just a luxury, but a necessity for operational efficiency and safety. Edge computing significantly amplifies this capacity, reshaping the dynamics of how data is processed and utilized in industrial environments.

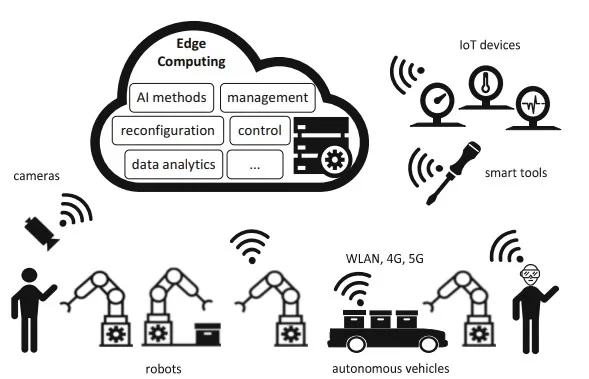

An exemplary case of EC’s application is seen in production lines where cooperating robotic arms work in unison. By offloading data analytics and processing tasks to the edge, closer to where actions are executed, EC optimizes the production workflow and supports the creation of smart, self-organizing manufacturing systems.

Moreover, applications in industrial environment monitoring, grid system controls, and extensive networks of wireless sensors and actuators are increasingly incorporating EC to enhance their capabilities. For instance, products like the Bosch IoT Gateway illustrate the practical advantages of EC by offering IIoT solutions with open APIs and diverse development tools for edge service creation. Such innovations underscore the tangible benefits of integrating EC into the IIoT, as depicted in the figure below.

Figure 2: Edge Computiong in industrial applications

Real-Time Data Processing at the Edge:

- Immediate Data Analysis: Edge computing allows for the immediate processing of data as it is generated. This real-time analysis is crucial for detecting anomalies, predicting maintenance needs, and responding to changes in industrial processes without delay.

- Reduced Latency: By processing data locally at the edge, the time taken to send data to a central server and receive a response is significantly reduced. This reduction in latency is vital for applications where even milliseconds matter, such as in automated manufacturing lines or safety monitoring systems.

- Data Prioritization and Filtering: Edge computing enables the sorting and filtering of data at its source. This means only relevant data is sent to the cloud or central systems, reducing network traffic and focusing on the most critical information for decision-making.

Autonomous Decision-Making Capabilities:

- Self-Contained Systems: With advanced algorithms embedded in edge devices, these systems can make autonomous decisions. For instance, a sensor detecting a temperature rise beyond a threshold can autonomously initiate cooling systems without waiting for central server instructions.

- Predictive Maintenance: Machine learning models running on edge devices can predict equipment failures before they occur. By analyzing data trends in real-time, these systems can schedule maintenance activities proactively, thus avoiding costly downtimes.

Integration with Advanced Technologies:

- AI and Machine Learning: Incorporating AI and machine learning at the edge transforms IIoT devices from mere data collectors to intelligent units capable of learning from data patterns, enhancing their decision-making accuracy over time.

- Digital Twins: Edge computing supports the implementation of digital twins, where real-time data from physical assets is used to create dynamic, virtual representations. These digital twins can be used for simulations, monitoring, and optimizing industrial processes.

As EC continues to evolve, it does not come without challenges. The infrastructure required to support these advanced capabilities must address issues of scalability, interoperability, and security. However, the successful implementation of EC in existing IIoT solutions serves as a testament to its potential, encouraging further exploration and adaptation of EC paradigms to meet the growing demands of the IIoT industry.

Challenges and Advanced Solutions in Edge Computing for IIoT

The integration of edge computing into the Industrial Internet of Things (IIoT) heralds a transformative phase in industrial operations. However, this integration is not without challenges. This section delves into the key challenges faced in implementing edge computing in IIoT environments and the advanced solutions being developed to address these challenges.

- Scalability and Management

As the number of edge devices increases, the scalability of the network and the complexity of managing these devices become significant concerns. Ensuring consistent performance across a sprawling network of diverse devices is a daunting task.

The Use of cloud-based management platforms offer centralized control and orchestration of edge devices. Implementing containerization and microservices architectures can also provide scalable and flexible deployment options.

- Data Security and Privacy

The decentralized nature of edge computing poses unique security and privacy challenges. Data processed at the edge can be susceptible to interception, manipulation, or unauthorized access.

So, Advanced encryption methods and secure communication protocols becomes essential. Additionally, deploying blockchain technology can enhance data integrity and traceability. Implementing robust access control and identity management strategies is also crucial.

- Network Connectivity and Reliability

Maintaining consistent and reliable network connectivity in diverse industrial environments, especially in remote or harsh locations, is challenging. Mesh networking topologies ensure network resilience and redundancy, and the adoption of 5G technology can also provide high-speed, low-latency connections ideal for edge computing applications.

- Energy Efficiency

Many edge devices, especially those in remote locations, have limited power resources, making energy efficiency a key concern. To resolve that, the development of low-power edge computing hardware and the use of energy harvesting technologies is the main solution. Optimizing software to reduce the energy consumption of data processing and transmission tasks.

While edge computing brings a wealth of benefits to IIoT, addressing its inherent challenges is crucial for its successful implementation through innovative solutions.

Conclusion and Future Trends

As the IIoT evolves, edge computing is set to play a pivotal role in this transformation. New trends and emerging innovations are shaping the landscape of edge computing in the realm of IIoT.

These developments will drive efficiency, enhance performance, and open new avenues for industrial applications.

The integration of Artificial Intelligence (AI) with edge computing is expected to advance significantly. AI algorithms will increasingly run on edge devices, enabling real-time analytics and decision-making directly at the data source.

The integration of edge computing with robotics and autonomous systems will enhance their capabilities in industrial environments.

Digital twin technology will increasingly leverage edge computing to create real-time virtual replicas of physical IIoT systems.

With sustainability becoming a key concern, future edge computing solutions in IIoT will focus on energy efficiency and green technology. Incorporating energy efficient technologies into edge devices, enables them to generate power from environmental sources like solar, thermal, and kinetic energy.

In summary, the future of edge computing in IIoT is marked by a synergy of technological advancements, from AI and 5G to sustainability-focused innovations. These trends indicate a shift towards more autonomous, efficient, and secure industrial operations, paving the way for a new era of IIoT solutions that are agile, intelligent, and eco-friendly. As these technologies mature, they will undoubtedly redefine the scope and impact of IIoT across various sectors.

References

- 3GPP ETSI TS 23.501. System Architecture for the 5G System (5GS). V16.6.0, 2020-10.

- Nurul Huda Mahmood, Nikolaj Marchenko, Mikael Gidlund, Petar Popovski, “Wireless Networks and Industrial IoT”, Springer, https://doi.org/10.1007/978-3-030-51473-0

- Erkki Harjula et al. “Edge Computing for Industrial IoT: Challenges and Solutions”, Springer Nature Switzerland AG 2021.

- Khan, W. Z. et al. 2020. “Industrial internet of things: recent advances, enabling technologies and open challenges”. Computers & Electrical Engineering 81(urtarrilak 1): 106522. doi:10.1016/j.compeleceng.2019.106522